Do you need a milk cooling tank?

Call us now

THE MILK PRE-COOLER

Ets CHARRIAU present a new designthe modular heat exchanger tube, one application of which is the efficient pre-cooling of milk on the farm

To meet all possible configurations, several types of milk pre-coolers are available:

The TEM-Classfor milking rates up to 4500 litres/hour.

The TES-Fit and TES-Ecofor a less expensive installation.

From a sanitary point of view, inspection and control of the TEM components can be carried out at any time. The design of the connections of the TES and TEM complies with the sanitary standards recommended by authorised organisations such as EHEDG ASEPT SAS for Europe and 3A sanitary standards for the USA. The exchanger is located in the extension of the milking equipment and before the milk tank, its cleaning is done by the milking machine washing and its purging is automatic.Translated with www.DeepL.com/Translator (free version)

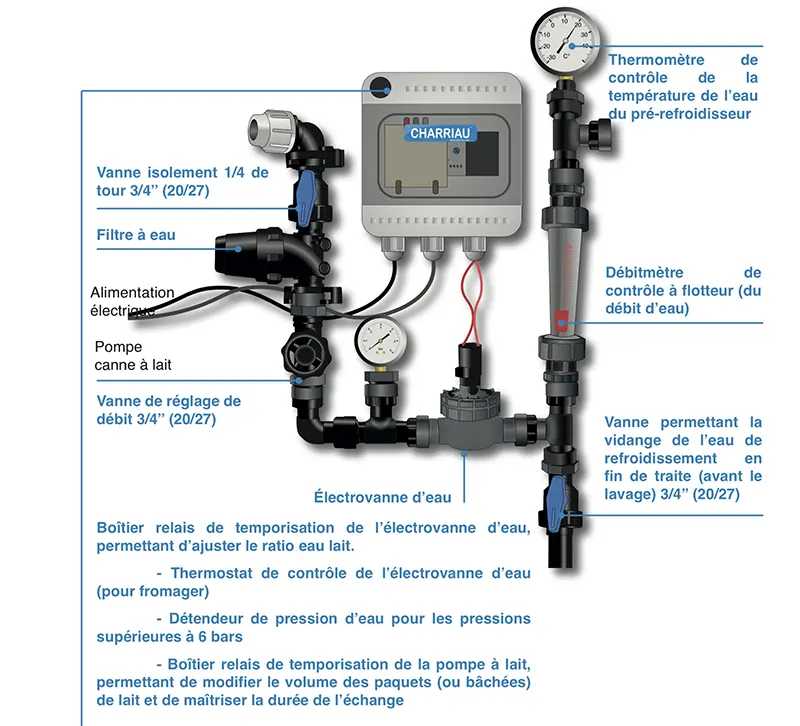

Our pre-coolers are the only ones to offer a control panel that allows the milk/water ratio to be controlled and regulated.

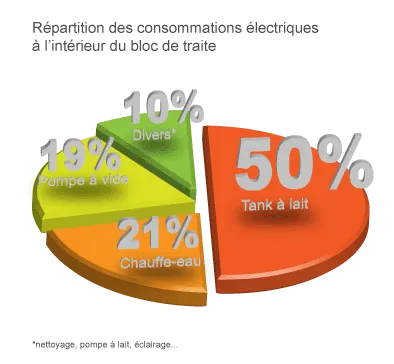

The tank is the main consumer

Calculation for a production right of 700 000L/year.

*Source: Institut de l’élevage

Reduce your electricity bill by €200

per 100,000 litres of milk produced,

CHARRIAU guarantees and commits to the results obtained.

Various testimonies and publication

I have known about the product for a long time, having invested in a plate unit a few years ago.

This unit was discontinued because its performance was poor and maintenance too expensive.

I have known about the product for a long time, having invested in a plate unit a few years ago.

This unit was discontinued because its performance was poor and maintenance too expensive.

I had two problems: the pre-cooler was undersized and the results were not very good (milk temperature of 26°C) and a constant overflow of water into the troughs.

I therefore spoke about all these difficulties to the milk technician at my dairy. He came back to see me with a technician from the CHARRIAU company. We studied together how to use water as rationally as possible.

He also clearly explained to me how a milk pre-cooler works and did the calculations to determine the right volume for me.

So I bought a linear tubular unit (all stainless steel) with a capacity of 30 l, with 72 m of heat exchange. For comparison, the previous unit had only 24 m of heat exchange.

It goes without saying that today I have a high-performance device that allows me to regularly have milk at 17°C at the outlet of the milk pump to the milk tank with water at 12°C.

A control panel allows me to check that my machine is working properly and to set the exact amount of water needed (1.5l of water per litre of milk)

As for the redistribution of water, this is managed automatically. The water used by the milk pre-cooler is stored for a short period in a 2500l tank and injected under pressure into my farm’s network. I can supply all the existing troughs, including those outside the building.

When the tank is empty, the water from the well takes over. So I don’t have to intervene, everything is automatic. I recommend a 3500l tank so that I don’t have to reduce the water flow when the milk flow is at its maximum (milking with two milkers)

The return on this investment will be between three and four years maximum.

This summer period gives me even more reason to have made this choice because despite the heat wave the running time of my tank is relatively reduced.

We installed our Charriau pre-cooler in February 2014. Although we were sceptical at first, our doubts were dispelled when we noticed that the milk cooling tank hardly cooled down at all. Since the installation, it only switches on at the end of milking, which will considerably reduce our electricity bill. As for the water used, we have adjusted the flow rate to store just the amount we need for pre-washing the milking machine and cleaning the parlour. So there is no waste!

“What determined us to choose a CHARRIAU pre-cooler was the manufacturer’s performance guarantee. Indeed, the milk is pre-cooled to less than 17°C on average over the year, as the company’s sales representative announced. Moreover, the system is perfectly adapted to my milking robots. Today, I save more than 4000 euros per year on the cooling of my milk tank. Jean Lou, partner in the farm.

“After studying the operation of several types of pre-coolers (plate and tubular), I did not wish to install a plate pre-cooler which requires regular maintenance (joints between the plates) and requires upstream filters to be changed daily, so I made the choice to invest in the CHARRIAU pre-cooler when the milking robot was installed. It allows me to cool my milk to 16°C in this summer period, which corresponds to a saving of more than 55%, as the milk tank only rarely starts up. The advantage is that there is no maintenance to be carried out as the pre-cooler is properly cleaned twice a day during the robot’s programmed washing, it does not require any additional maintenance. This investment is profitable, in less than 4 years the system will pay for itself thanks to the reduction in electricity consumption” Julien, manager of the farm.

“We chose to install the CHARRIAU linear model because it offers several advantages: First of all, it allows us to replace the milk cane between the robot and the milk tank. Moreover, in robotic milking, after the milk collection, at the start of the robot and the milk cooling tank, the volume of milk is too low to start the refrigeration unit, in which case the milk would be frozen quickly, the cooling is therefore programmed 3 hours after the collection, fortunately, the temperature of the milk is lowered to less than 17°C thanks to the pre-cooler, which reduces the development of germs and lipolysis during this critical period. We strongly recommend the installation of this equipment at the outlet of your robot, it will allow you to preserve the quality of the milk and to reduce the operating time of the milk tank.»